S3 Inline (Vacuum)

S3 Inline Sensor (Vacuum-Ready)

- For inline monitoring when material shape and size doesn’t allow for two-sided sensors

- Noncontact measurement of sheet resistance, sheet conductance, resistivity, thickness, and emissivity

- Range options from .005 ohms/square to 100,000 ohms/square

- Great for monitoring cross-web and down-stream consistency

- Detachable probe – add sensors at any time to widen range or add measuremnt points

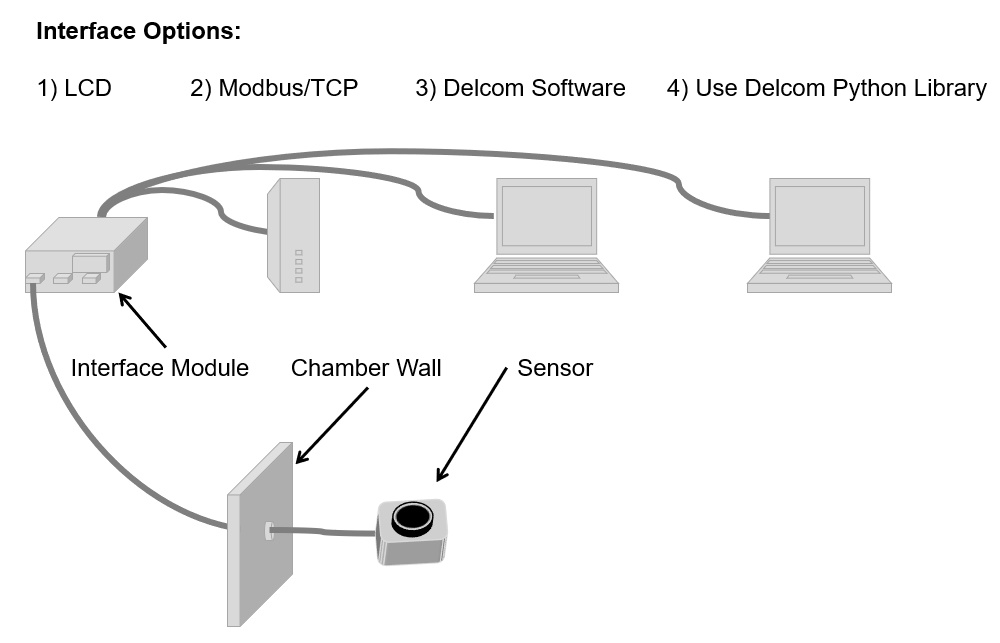

- Monitor and control remotely via Delcom software, MODBUS/TCP, or Python library

- Constructed of vacuum-compatible components

ADVANTAGES OF NONCONTACT EDDY CURRENT

REDUCE PRODUCT AND LABOR COSTS

|

DISPLAYS

PHOTOVOLTAICS (PV)

ARCHITECTURAL GLASS (LOW-E)

SMART GLASS: COMMERCIAL & RESIDENTIAL ARCHITECTURAL GLASS, AUTOMOTIVE & AEROSPACE

PRECISION OPTICS AND OPTICAL COATINGS AEROSPACE AND DEFENSE

|

ENERGY DEVICES

PRINTING CONDUCTIVE INKS

FLEXIBLE ELECTRONICS, HEATING, SHIELDING, ANTENNAS

METALIZED CAPACITOR FOIL EMI AND RF SHIELDING CONVERTING AND PACKAGING

REFLECTIVE (SAFETY) MATERIALS MEDICAL IMAGING MATERIALS MISCELLANEOUS

|

TYPES OF MEASUREMENTS POSSIBLE

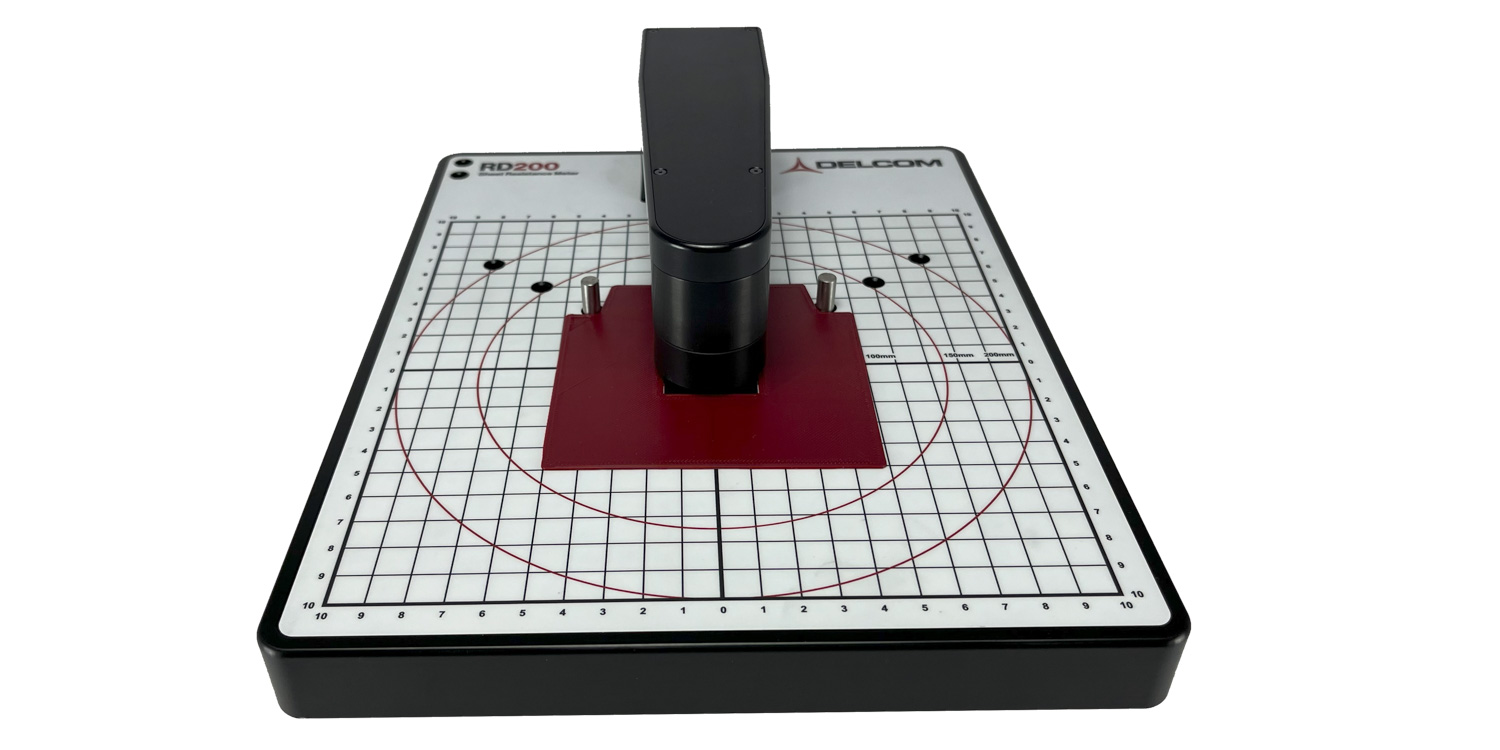

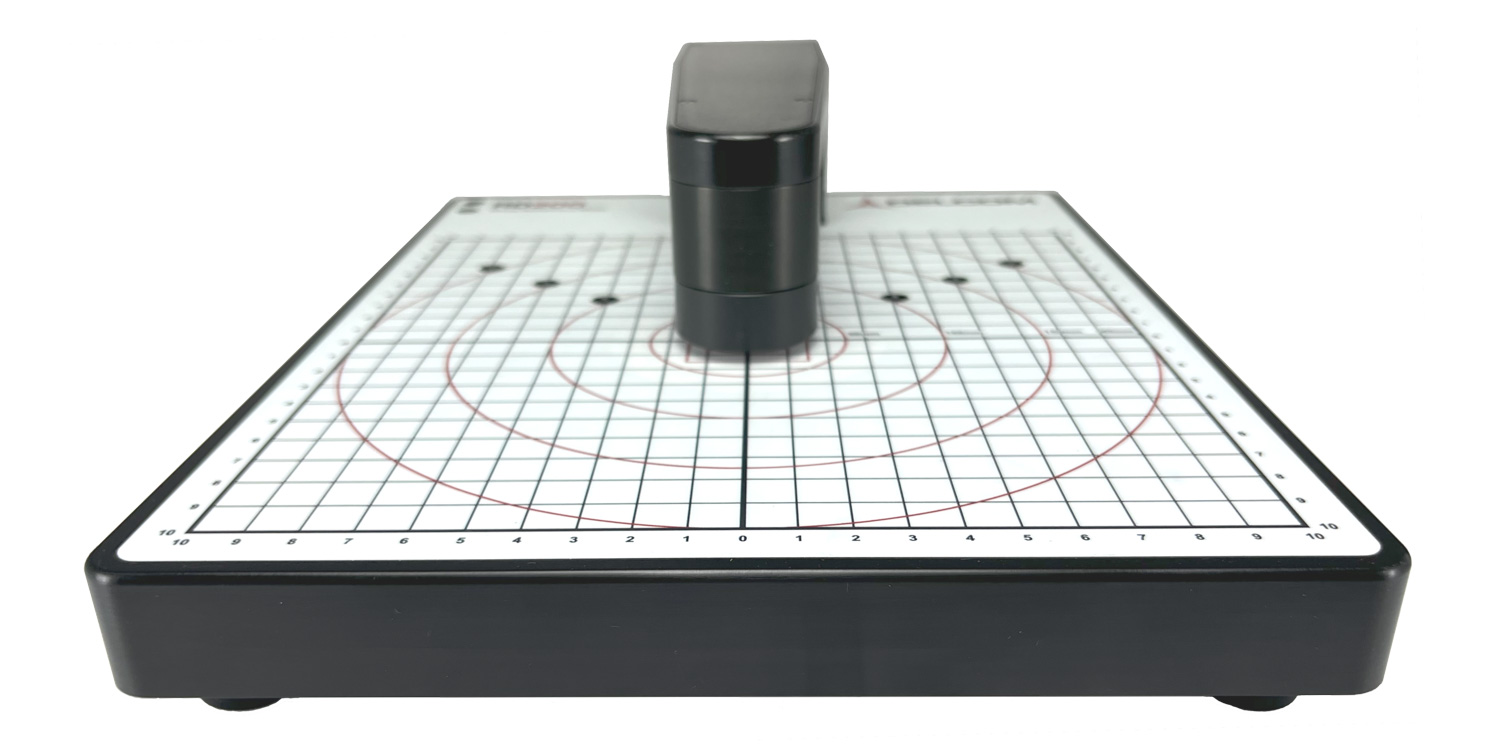

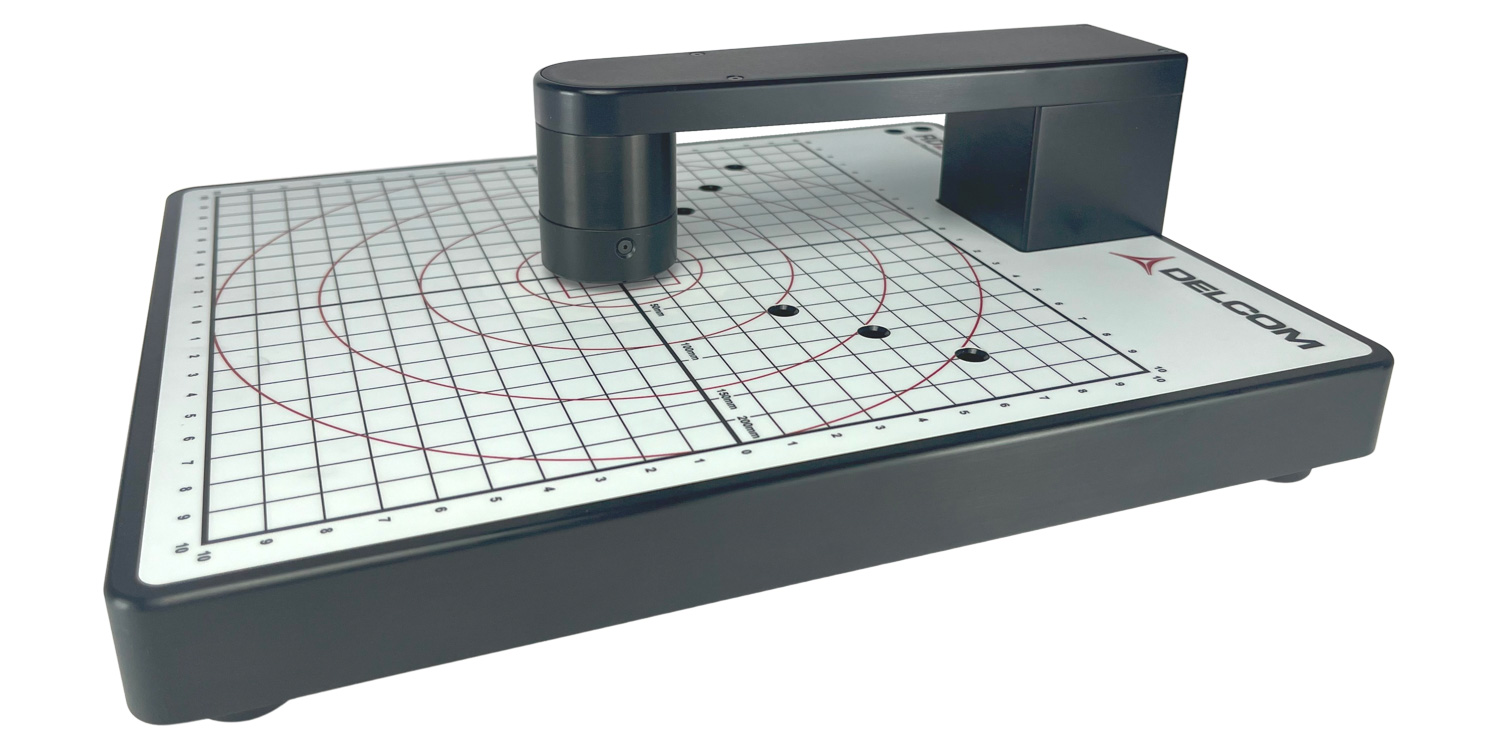

SENSOR DIMENSIONS Sensor type: Single-sided SENSOR CONFIGURATION Vacuum chuck: NA SENSOR RANGES—Select two adjacent ranges. ×10 From 5 to 100,000 ohms/square MATERIAL REQUIREMENTS Minimum thickness: No minimum |

POWER AND OPERATING TEMPERATURE

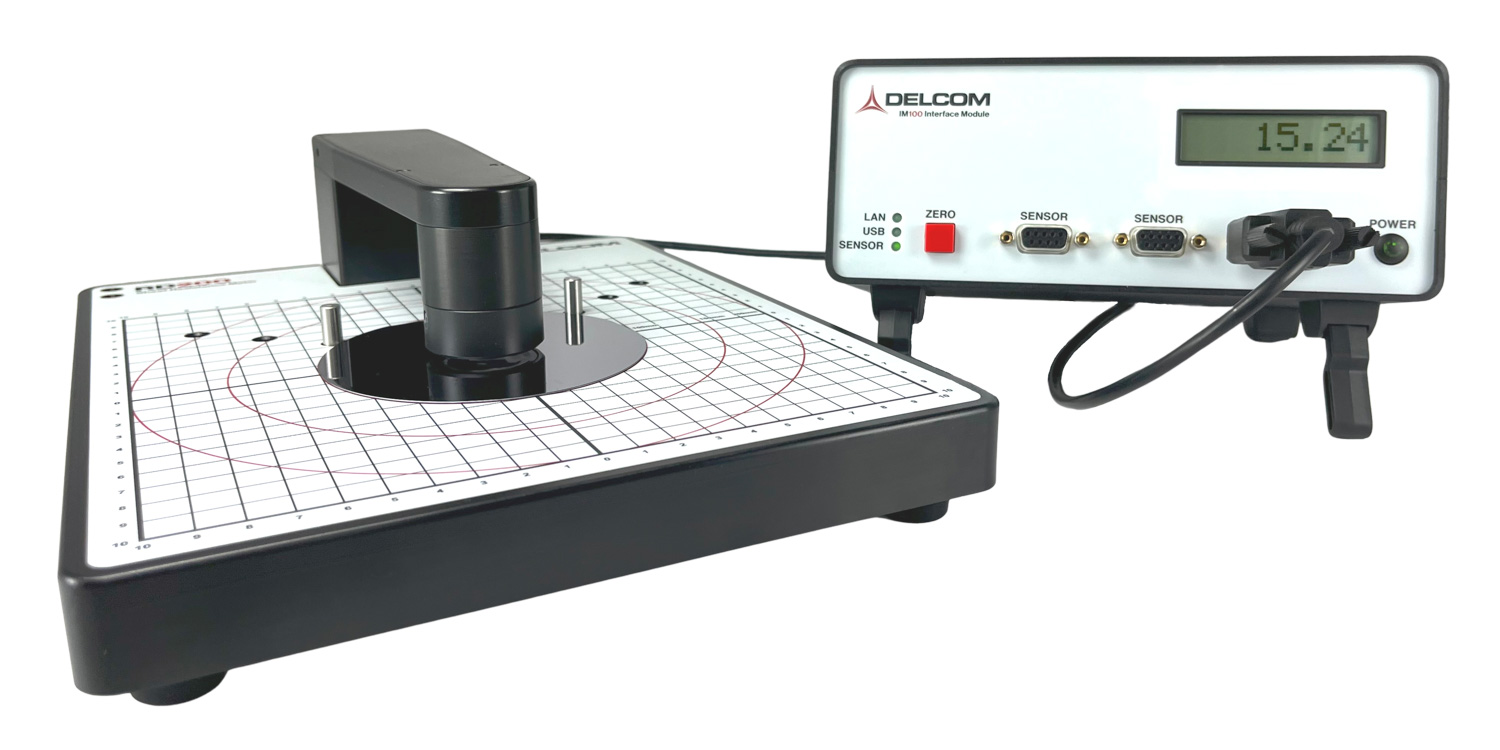

Power input: 100–120/200–250 VAC DIMENSIONS AND WEIGHTS Sensor: 7×5.5×4.5, .3kg CONFIGURATION AND INTERFACE

|

| RESPONSE & DISPLAY RATES

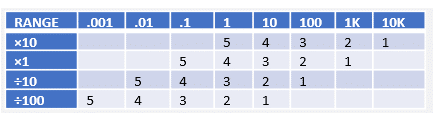

Delcom meters sample material every 30 ms. Delcom firmware and software perform pipeline averaging and display 8 averaged readings every 240 ms. ACCURACY Delcom meters are calibrated to better than 99.9% accuracy against National Institute of Standards and Technology (NIST) standards. User can calibrate a meter with one standard in one minute. RESOLUTION Significant digits available at each order of magnitude for each of the four meter ranges.

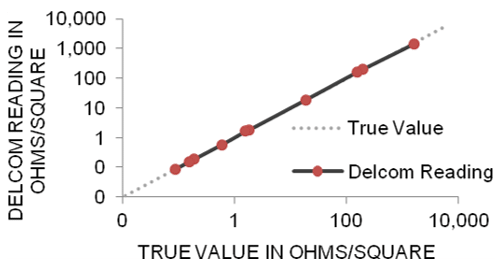

LINEARITY Delcom guarantees no more than 3% deviation from the true sheet resistance value of tested material. The chart below shows a Delcom meter tested against 10 NIST, VLSI, and MSA standards.

|

REPEATABILITY

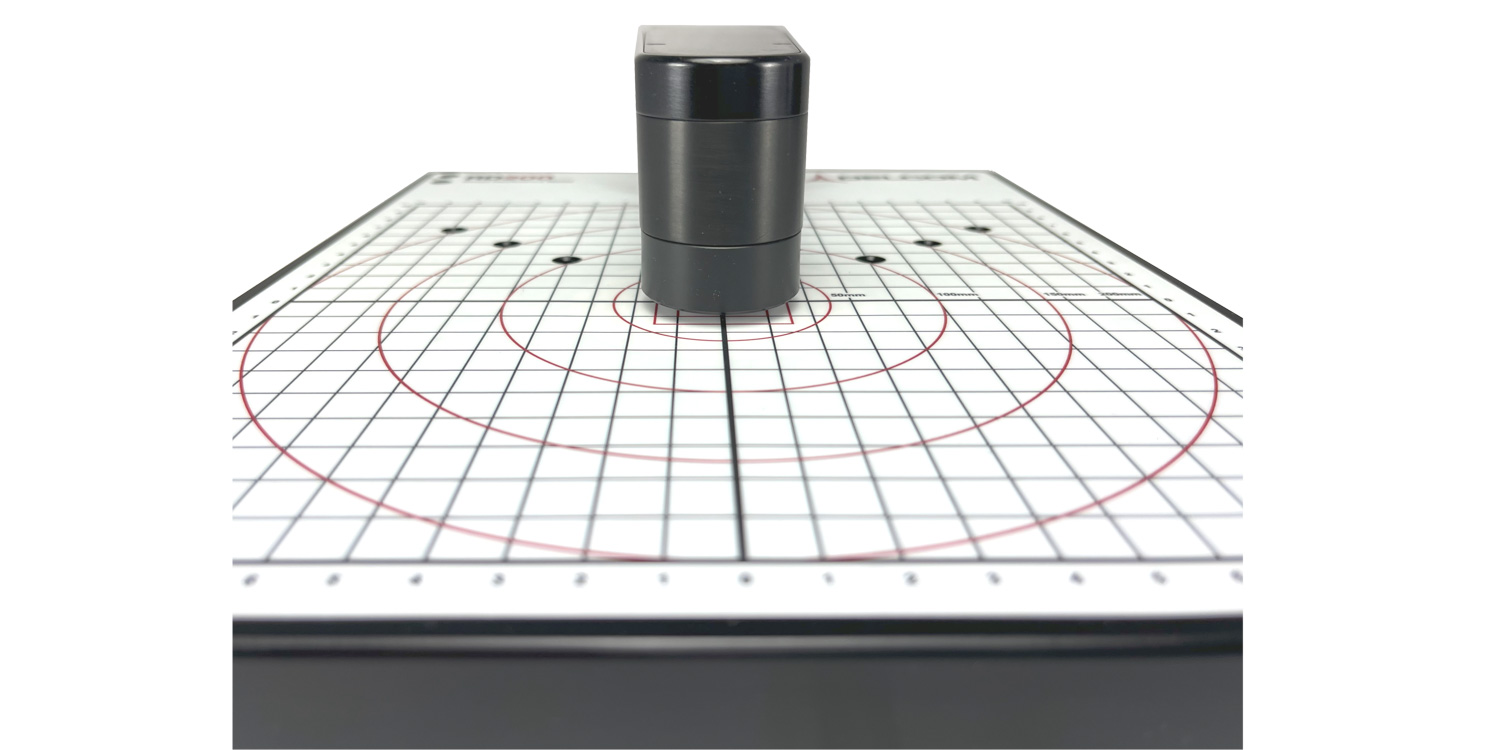

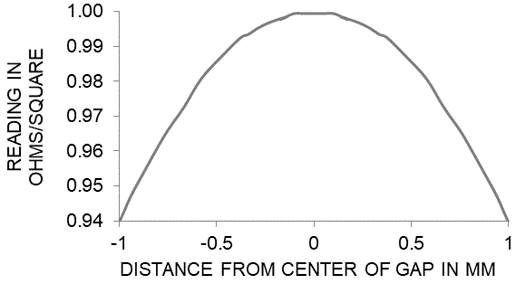

Delcom meter readings are effectively 99.9% repeatable if sample placement and environmental factors, such as temperature, are held constant. TEMPERATURE COMPENSATION The baseline readings of eddy current instruments drift with changes in ambient temperature. Delcom benchtop sensors are compensated so they drift no more than .04% of total resolution per degree Celsius per hour. LIFT-OFF As a conductive layer is moved away from the face of the sensor, the sensor will read the material as less and less conductive. This effect is easily managed by placing the sensor on top of the conductive layer, mounting the sensor into a stage and placing sample conductive side down or at a known elevation, or suspending the sensor above the material at a known elevation.

|

INLINE SOFTWARE

User selectable units of measurement

Software modes optimized for most common user needs to include

Data record, analysis, and export

|

User selectable performance variables

|

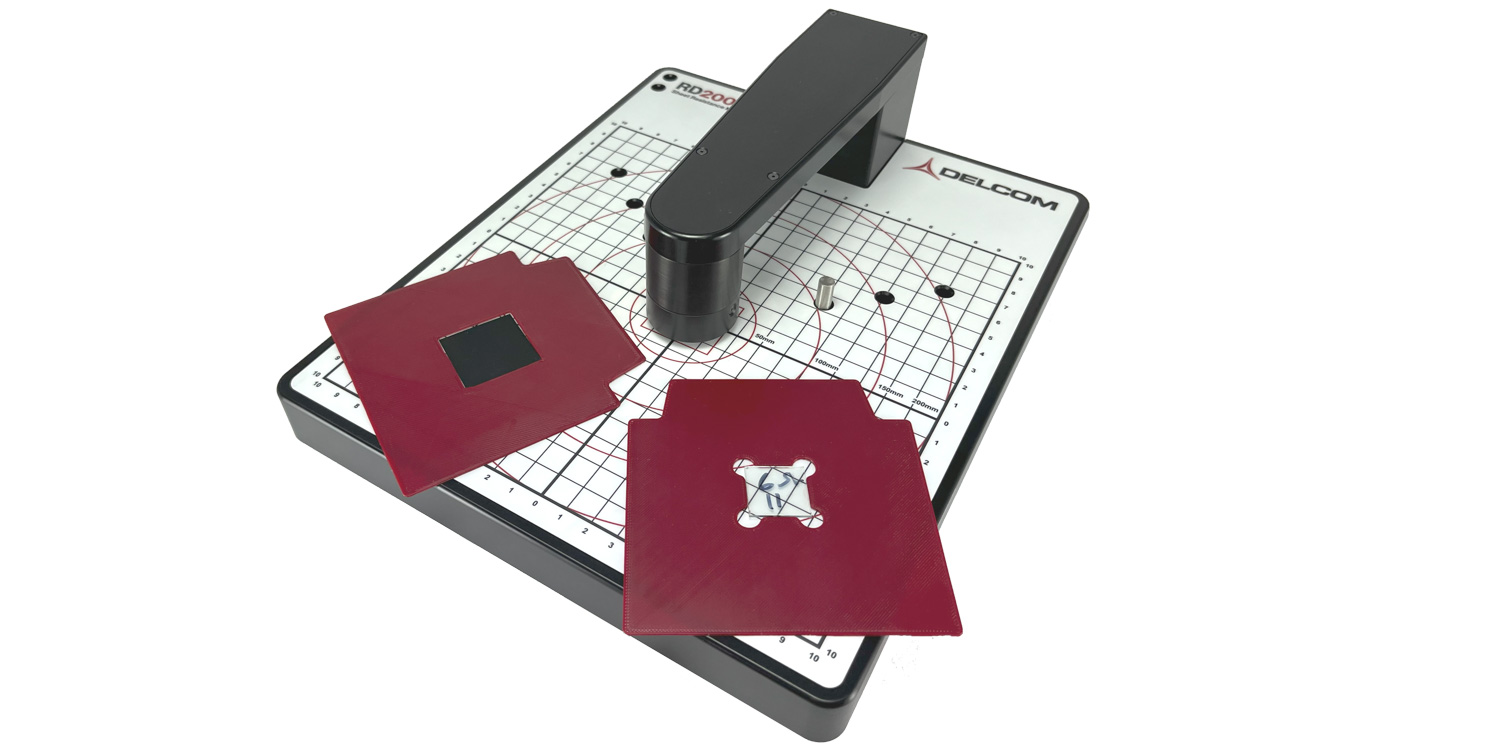

| EXTEND SENSOR RANGE

Delcom sensor with ship with any two adjacent ranges as listed below. Purchase additional sensors to achieve the full range of Delcom sensors. ×10 From 5 to 100,000 ohms/square USE PYTHON LIBRARY TO BUILD CUSTOM INTERFACE CUSTOM GAP AND SPOT SIZE |

ADD ADDITIONAL SENSORS

The IM100 Interface Module supports additional sensors providing more range, large or smaller gaps, or alternative shape/size.

ADD OPTIONAL STAGE Use optional stage to ensure material is introduced into sensor gap at the optimal elevation and to control for X Y location of material

SPECIFY VACUUM-COMPATIBLE COMPONENTS Specify vacuum-compatible components acceptable for high vacuum applications.

|

Veteran Owned

Veteran Owned Veteran Owned

Veteran Owned