Eddy current sensors have revolutionized non-contact measurement in industries requiring precision and reliability. Delcom, based in Minneapolis, specializes in developing cutting-edge eddy current sensors for sheet resistance measurement. These advanced tools deliver unparalleled accuracy, supporting a wide range of applications in semiconductors, materials research, and electronics manufacturing.

What is an Eddy Current Sensor?

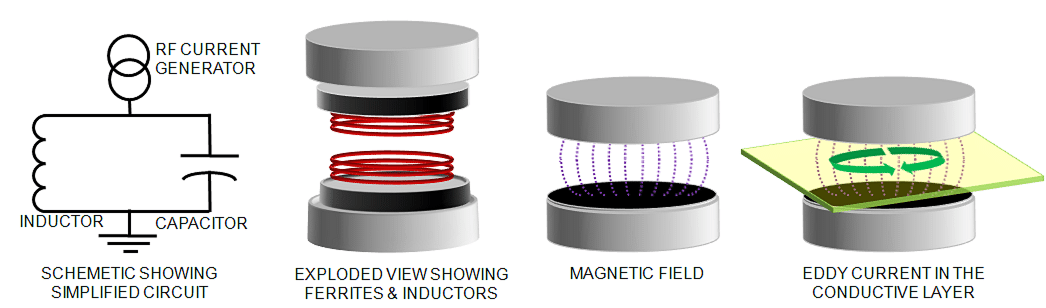

An eddy current sensor operates on the principle of electromagnetic induction to measure the electrical conductivity and resistance of materials. By generating a magnetic field and analyzing the resulting currents induced in the material, these sensors provide non-contact, highly accurate measurements.

Key Benefits of Eddy Current Sensors:

- Non-Contact Measurement: Preserves material integrity during testing.

- High Sensitivity: Captures even minute variations in resistance or conductivity.

- Versatility: Effective for diverse materials, including metals, coatings, and composites.

Delcom’s advanced eddy current sensors are engineered to meet the highest standards of precision, making them an indispensable tool in industries requiring accurate sheet resistance measurement.

Applications of Eddy Current Sensors in Sheet Resistance Measurement

Delcom’s eddy current sheet resistance sensors serve numerous industries by delivering consistent and reliable results.

Semiconductor Manufacturing

Measure thin films and conductive layers on wafers with unmatched precision, ensuring optimal performance in microchips and electronic components.

Material Science

Support research and development by characterizing electrical properties in metals, alloys, and thin films.

Solar Panels and Photovoltaics

Optimize the efficiency of photovoltaic cells by measuring the resistance of transparent conductive coatings.

Aerospace and Automotive

Monitor the quality of coatings and conductive materials used in advanced engineering applications.

Delcom’s sensors provide the accuracy and repeatability necessary for these high-stakes applications.

Delcom Eddy Current Sheet Resistance Sensors: Features and Advantages

Delcom’s eddy current sensors are designed for ease of use, precision, and adaptability across multiple industries.

Key Features:

- Non-Destructive Testing: Ideal for sensitive and delicate materials.

- High Accuracy: Measures resistance with exceptional precision, even in ultra-thin films.

- Real-Time Feedback: Delivers immediate results to optimize processes.

- User-Friendly Interface: Simplifies operation and integration into workflows.

Why Choose Delcom?

- Customized Solutions: Tailored to meet the unique needs of your application.

- Durable Design: Built to withstand demanding industrial environments.

- Innovative Technology: Incorporates the latest advancements in eddy current sensing.

Eddy Current Technology: Advancing Sheet Resistance Measurement

Eddy current technology represents the future of non-contact sheet resistance measurement. Unlike traditional methods, eddy current sensors eliminate the risk of material damage or contamination, ensuring more reliable and repeatable results.

How Eddy Current Sensors Work:

- Magnetic Field Generation: The sensor creates an alternating magnetic field.

- Eddy Current Induction: When placed near a conductive material, eddy currents are induced.

- Resistance Analysis: The sensor measures the resulting changes in the magnetic field to calculate resistance.

This innovative approach enables highly accurate and efficient measurements, even for complex geometries and challenging materials.

Electrochemical Society Resources on Eddy Current Technology

Energy Efficiency and Sustainability with Delcom Sensors

Delcom’s eddy current sensors align with sustainable practices by reducing material waste and energy consumption. By offering non-contact, non-invasive testing, these sensors minimize the need for destructive methods and rework, promoting eco-friendly processes.

Industries That Benefit from Delcom Eddy Current Sensors

Electronics Manufacturing

Ensure quality and consistency in conductive films and circuit components.

Renewable Energy

Enhance the performance of solar cells and other energy-efficient technologies.

Automotive and Aerospace

Monitor critical components for conductivity and coating uniformity.

Academic and Industrial Research

Support material characterization and innovation with precise, reliable measurements.

Delcom’s expertise and advanced technology make their sensors the preferred choice across diverse sectors.

Why Delcom is the Trusted Leader in Eddy Current Sensors

Delcom has built a reputation for excellence in measurement technology, combining innovation with unparalleled customer support.

What Sets Us Apart:

- Proven Expertise: Decades of experience in non-contact measurement solutions.

- Advanced Technology: State-of-the-art eddy current sensors designed for precision.

- Customer-Centric Approach: Providing tailored solutions and ongoing technical support.

- Commitment to Quality: Delivering reliable, high-performance tools that exceed industry standards.

Contact Delcom for Eddy Current Sensor Solutions

Delcom’s eddy current sensors are revolutionizing the way industries measure sheet resistance and conductivity. Contact us today to learn more about our advanced solutions and how they can enhance your processes.

Veteran Owned

Veteran Owned Veteran Owned

Veteran Owned