Packaging

What is Measured

Delcom sensors are widely used to measure the metalized layer in barrier films in the food packaging industry. This includes metals such as:

- Aluminum (by far the most widely used)

- Nickel

- Chromium

These metals are regularly deposited on substrates such as:

- Polypropylene, biaxially-oriented polypropylene (BOPP), accounts for almost 50% of metalized packaging material

- Polyethylene terephthalate (PET), polyester

- Nylon

- Polyethylene

- Cast polypropylene, cast OPP

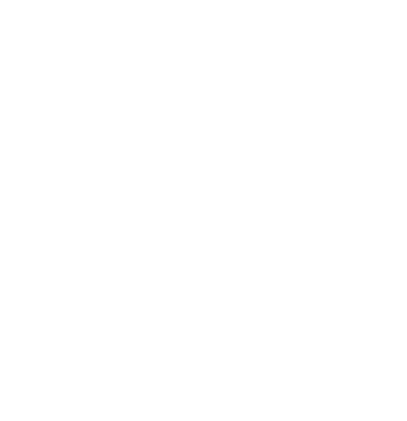

Depositing these metals onto these substrates will create a metalized layer. In the barrier packaging industry, this layer is often substituted for a foil layer in the traditional barrier packaging material “stack”. Below is one possibly way the metalized layer is employed in barrier packaging:

Figure 1: Barrier packaging cross section

Metallizers typically do not have a target sheet resistance for their metalized film because the function the film is serving is often not related to the conductance of electricity. However, metalized film manufactures care about the thickness of the metalized layer as it directly contributes to the performance of other functions for which the material is designed.

Specifically, in the case of food barrier films, manufacturers want to limit the ability of a permeant to transfer through it. As an example, a deposited layer of 0.5 micrometers of Aluminum on PET results in performance of:

- Moisture: 0.8 g/m2·day

- Oxygen: 1.2 mL/m2·day

- UV light transmittance: 5%

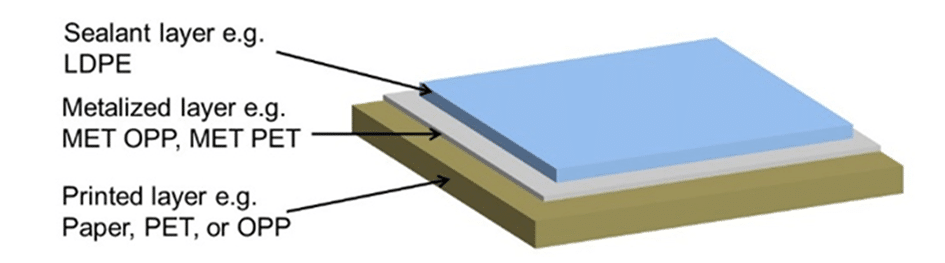

There are various methods for monitoring deposition thicknesses during the PVD process, but the best and most precise is through the use of a Delcom Sheet Resistance meter. By simply inputting the bulk resistivity of the material (Aluminum, Nickel, Chromium, or any other material), the Delcom sensor will perform the necessary calculation and display in real-time the thickness of the deposited layer. The simple math performed by the Delcom meter “behind the scenes” involves dividing resistivity by sheet resistance to determine thickness.

Figure 2: the relationship between thickness, sheet resistance, and resistivity

To dig further into what the Delcom sensor is doing “behind the scenes”, let’s consider the challenge of monitoring the deposition of aluminum in real time. The user inputs the resistivity of aluminum: 2.82 × 10-6 ohm-cm into the Delcom terminal and begins the deposition process. During the process, the Delcom sensor recorders readings around 0.564 ohms/square. The Delcom software then divides the resistivity by the sheet resistance and displays to the operator the thickness of the deposed aluminum: 2.82 × 10-6 ohm-cm ÷ 0.564 ohms/square = 0.5 micrometers.

The converting industry has embraced metalized materials because of the increased shelf life of the product. These materials are most often manufactured using High-speed Physical Vapour Deposition (PVD) processes. Worth noting is a growing trend is that consumers want to be able to view the freshness of the food inside the packaging. Given this, the use of both aluminum foil and traditional roll-to-roll evaporated aluminum layers is slowly being phased into vacuum-deposited aluminum oxide (AlOx) coated packaging

In order to justify the higher cost of metalized materials these performance benefits must be carefully maintained through careful monitoring of the deposition process inline and in situ. Delcom sensors are the ideal tool to provide instantaneous monitoring of layer deposition to ensure the metalized layer is within acceptable thickness parameters.

Why Measure with Delcom

It is important to note that because eddy current meters rely on a magnetic field to achieve their reading, they have a number of advantages over four-point probes to include:

- Reliably approximates emissivity

- Is non-destructive

- Reads through insulating layers

- Measures moving material

- Provides nearly instantaneous readings

- Provides real-time process inspection

Employment Strategies

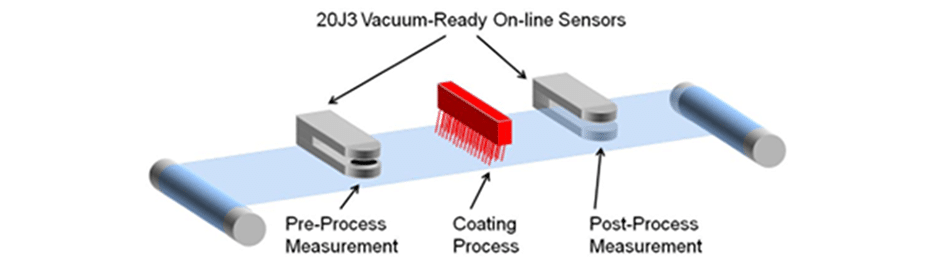

All delcom sensors come in one of two varieties: vacuum-ready and not vacuum-ready. Vacuum ready sensors are devoid of anodized materials, nickel coated hardware, and insulators that out-gas. In general, silver colored sensors are vacuum-ready while black anodyzed sensors are not.

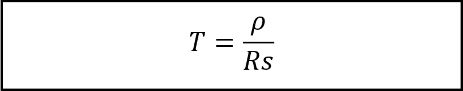

High-speed Physical Vapour Deposition (PVD) process is the most common method of manufacturing metalized film. In this process, a metal (most commonly Aluminum) is heated and evaporated in a vacuum chamber. Inside the chamber a roll of polymer film is unwound and the metal condenses onto the cooler substrate.

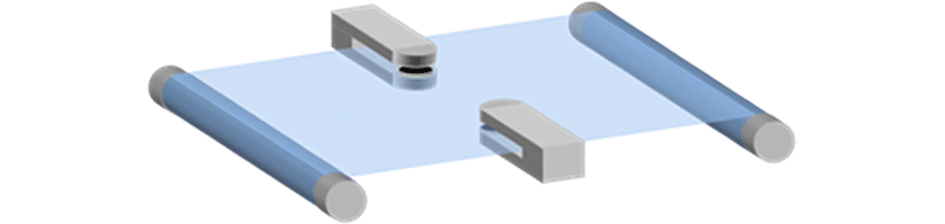

For in situ roll to roll process, the best placement for the Delcom sensor is inside the chamber just after the coating of the conductive material.

Figure 3: Delcom sensor monitoring in situ roll to roll deposition

Cross-Web & Downstream Monitoring

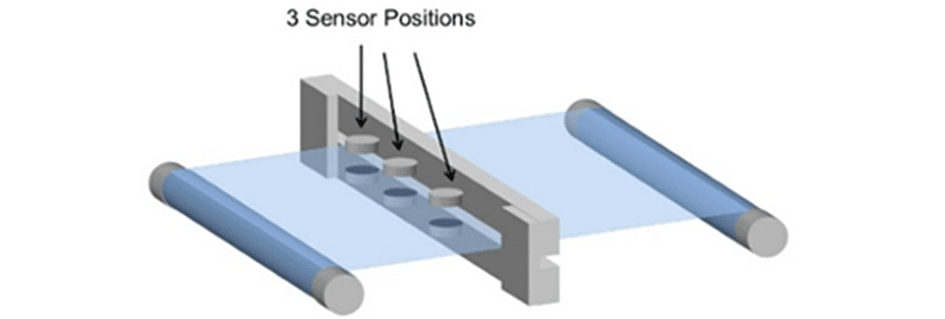

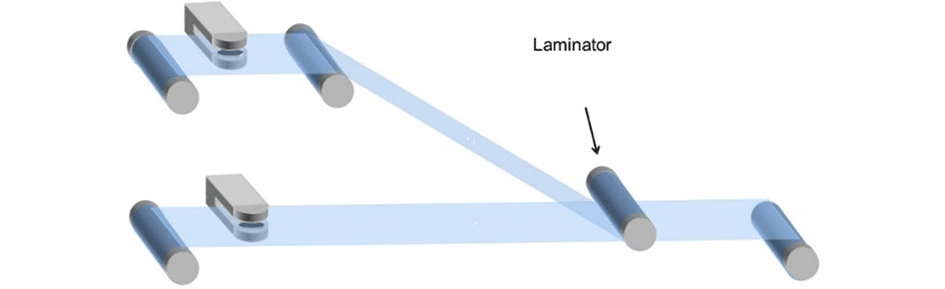

In general, Delcom sensor deployment strategies can include one or more of the following deployment tactics.

|

Deployment Strategy |

Image | Advantages |

|---|---|---|

| Single sensor single spot |  |

|

| Two sensors monitoring cross-web |  |

|

| Two sensors monitoring downstream |  |

|

| Multi-channel monitoring cross-web |  |

|

| Measure layers prior to lamination |  |

|

Recommended Sensors

Delcom recommends the following sensors based on the user’s material, stage of development, and application.

| Use case | Image | Recommended Sensor | Use case |

|---|---|---|---|

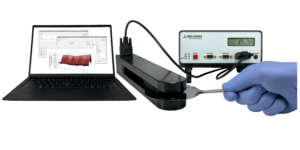

| Benchtop |  |

RD200 |

|

| Inline |  |

20J3 Hybrid |

|

| Inline |  |

20J3 Inline |

|

| Inline |  |

OEM |

|

| Inline |  |

Multisensor |

|

Recommended Sensor Range

Delcom sensors measure sheet resistance. Delcom makes sensors in four ranges – each range able to measure a different range of sheet resistances. When considering which sensor is right for a particular application, the right range of instrument must be selected based on the target sheet resistance of the material.

Figure 4: Delcom’s sensor ranges:

| Range Name | Min Sheet Resistance in ohms/square |

Max Sheet Resistance in ohms/square |

|---|---|---|

| x10 | 5 | 100000 |

| x1 | 0.5 | 10000 |

| ÷10 | 0.05 | 1000 |

| ÷100 | 0.005 | 100 |

Sheet resistance is – of course – associated with the target thickness of the deposited metals. So, in order to select the correct Delcom sensor range, the metals the metallizer intends to use must be known. So, for example, assume the metallizer will be depositing Aluminum, Nickel, and Chromium for three different products. The target thickness for all three products is 0.5 micrometers.

Figure 5: Target thickness of deposited metalized films

| Material | ρ (resistivity) in ohm-cm | Target Thickness in cm | Target sheet resistance in ohms-square |

|---|---|---|---|

| Aluminum | 2.82 × 10-6 | 0.00005 | 0.0564 |

| Nickel | 7 × 10-6 | 0.00005 | 0.1400 |

| Chromium | 13 × 10-6 | 0.00005 | 0.2600 |

According to this chart, the appropriate sensor range for this metallizer’s product is a ÷10 instrument (also called a 100N).

Veteran Owned

Veteran Owned Veteran Owned

Veteran Owned