Microwave Susceptors

What is Measured

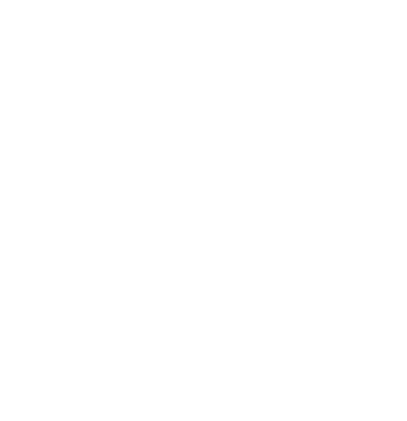

Delcom sensors can measure the metalized layer of microwave susceptors. Delcom sensors can be employed in situ as aluminum is deposited on PET (for example). They can also be employed in vacuum before or after the metalized layer laminated to its cardboard platform or sleeve. Finally, Delcom sensors can be used to measure the metalized layer of susceptors after/during patterning, die cutting, and gluing to paper, cardboard, or cellophane backing.

Figure X: Microwave susceptor cross-section

Why Measure with Delcom

Many converters are currently successfully manufacturing susceptors with a Delcom sensor. Microwave heating of food is a fairly tolerant process and a “too thick” layer results in only a minor inconvenience for the consumer. However, with increased competition within the food industry and more sophisticated cooking needs, the ability to precisely measure and – therefore control – the deposition process offers the manufacturer with a Delcom sensor a distinct advantage.

Delcom sensors allow the manufacturer to directly corelate a specific metal layer thickness with product performance. Offering a competitive advantage for the in-house converter and an additional marketing advantage for the contract converter.

In addition, the ability to optimize metal layer thickness during deposition will reduce waste, increase throughput, and save on aluminum costs. Given the over 30 year expected lifespan of the Delcom sensor, these savings more than justify the cost of the sensor.

It is important to note that because eddy current meters rely on a magnetic field to achieve their reading, they have a number of advantages over four-point probes to include:

- Is non-destructive

- Reads through insulating layers

- Measures moving material

- Provides nearly instantaneous readings

Provides real-time process inspection

Employment Strategies

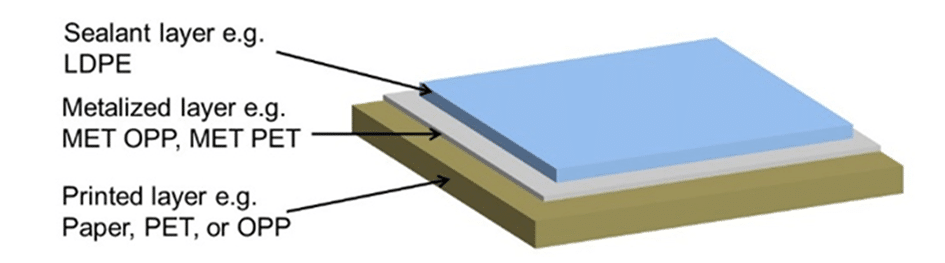

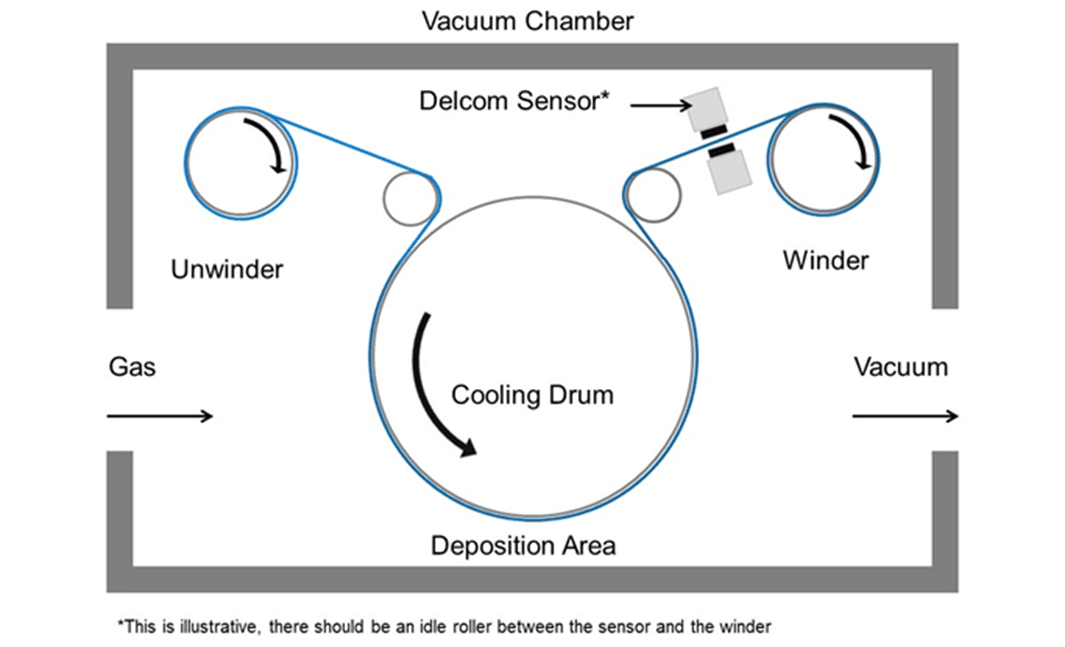

All delcom sensors come in one of two varieties: vacuum-ready and not vacuum-ready. Vacuum ready sensors are devoid of anodized materials, nickel coated hardware, and insulators that out-gas. In general, silver colored sensors are vacuum-ready while black anodyzed sensors are not.

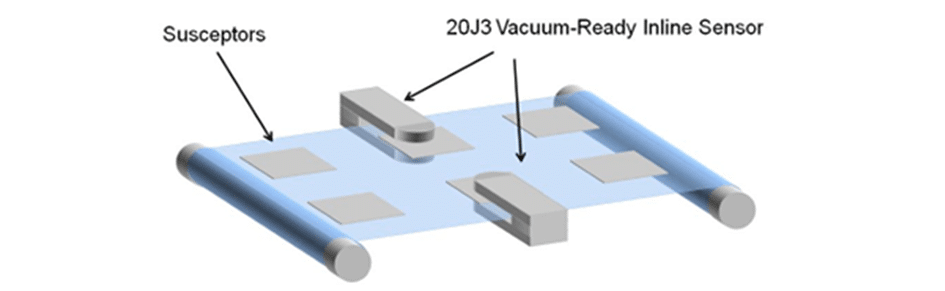

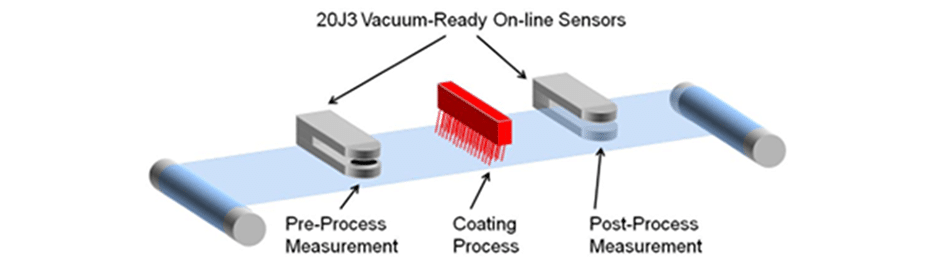

For in situ roll to roll process, the best placement for the Delcom sensor is inside the chamber just after the coating of the conductive material.

Figure X: Sensor placement in situ

Cross-Web & Downstream Monitoring

In general, Delcom sensor deployment strategies can include one or more of the following deployment tactics.

|

Deployment Strategy |

Image | Advantages |

|---|---|---|

| Single sensor single spot |  |

|

| Two sensors monitoring cross-web |  |

|

| Two sensors monitoring downstream |  |

|

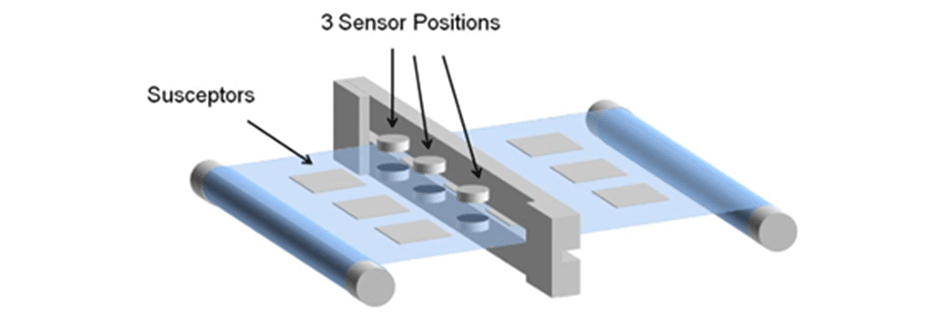

| Multi-channel monitoring cross-web |  |

|

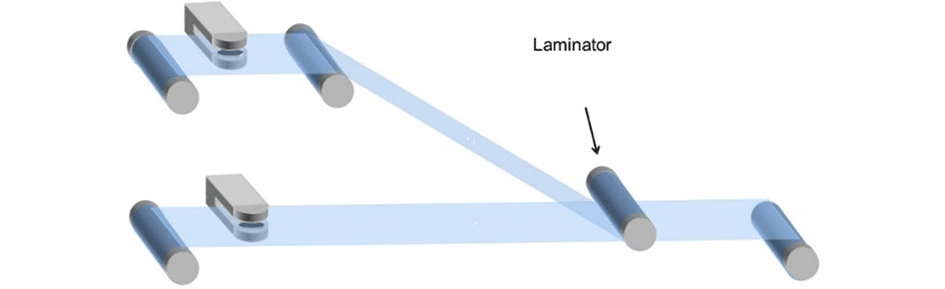

| Measure layers prior to lamination |  |

|

Recommended Sensors

Delcom recommends the following sensors based on the user’s material, stage of development, and application.

| Use case | Image | Recommended Sensor | Use case |

|---|---|---|---|

| Benchtop |  |

RD200 |

|

| Inline |  |

20J3 Hybrid |

|

| Inline |  |

20J3 Inline |

|

| Inline |  |

OEM |

|

| Inline |  |

Multisensor |

|

Recommended Sensor Range

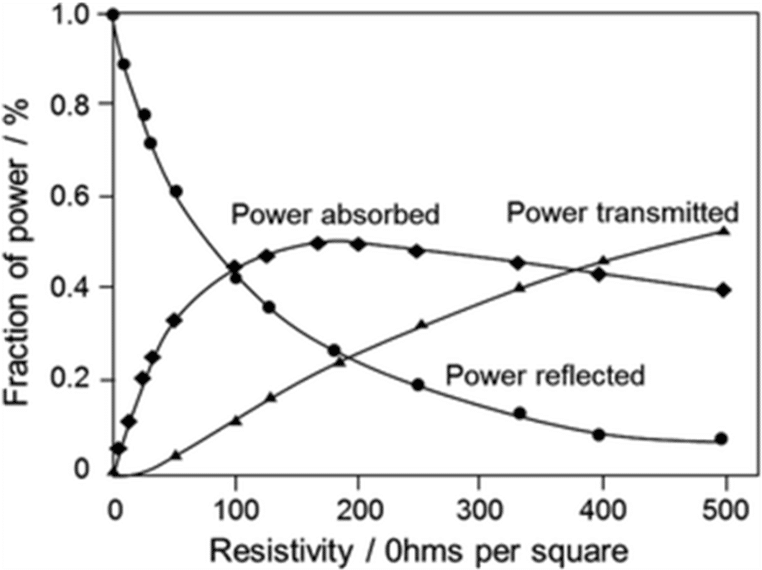

The active element of food packaging typically consists of a cardboard platform or sleeve that incorporates a metalized layer. When exposed to microwave radiation, this active layer induces an electronic vortex current within the susceptor. This current, in turn, heats the thin film, transforming it into an infrared cooking source.

The susceptor fabrication process aims to achieve an optimal sheet resistance of 188 ohms per square. Absorption efficiency increases as the surface resistance increases from zero until it peaks at around 188 ohms per square. Depending on the specific food item, the ideal range for surface resistance lies between 30 and 250 Ohms per square.

When susceptors possess a surface resistance of less than 188 ohms per square, they exhibit higher reflectivity than transmission. This can lead to potential oven damage and inadequate levels of infrared radiation-induced crisping. Conversely, susceptors with a surface resistance exceeding 188 ohms per square display greater transmission than reflection. However, this generates a relatively weak electronic vortex current, resulting in insufficient provision of infrared radiation.

Figure X: Power absorbed, transmitted, and reflected*

*Satoshi Horikoshi, Engineering of Microwave Heating, 28 November 2017, Microwave Chemical and Materials Processing, pp145-182

Delcom sensors measure sheet resistance. Delcom makes sensors in four ranges – each range able to measure a different range of sheet resistances. When considering which sensor is right for a particular application, the right range of instrument must be selected based on the target sheet resistance of the material.

Figure X: Delcom’s sensor ranges:

| Range Name | Min Sheet Resistance in ohms/square |

Max Sheet Resistance in ohms/square |

|---|---|---|

| x10 | 5 | 100000 |

| x1 | 0.5 | 10000 |

| ÷10 | 0.05 | 1000 |

| ÷100 | 0.005 | 100 |

The susceptor manufacturing process targets an effective sheet resistance of 188 ohms per square. However, depending on the food, optimum values lay between 30 and 250 per square. Therefore, the recommended instrument range for this application is “x10”.

Veteran Owned

Veteran Owned Veteran Owned

Veteran Owned