Applications

For over 40 years Delcom sensors have been used to achieve higher material and thin film quality in the following applications:

Auto Mirrors

Plastic and glass of varying thickness, shape, and curvature coated with Aluminum, silver, etc.

Batteries & Storage

Cathode, anode, electrode, current collector characterization during deposition, calendaring, and drying processes

Boules & Ingots

Verify doping, identify defects and dislocations

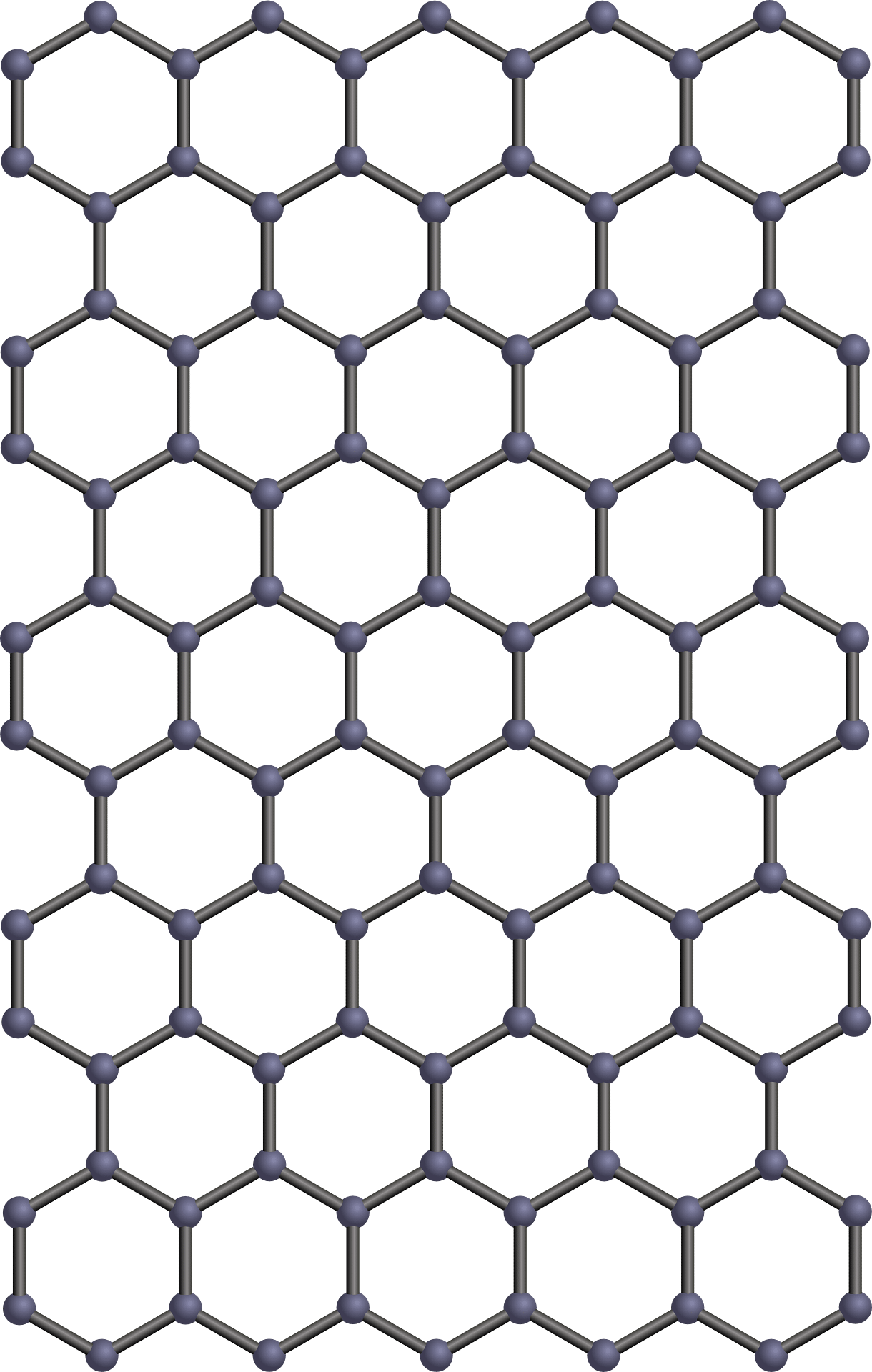

CNT and Graphene

In process monitoring during manufacture, in powder form, or coated on materials

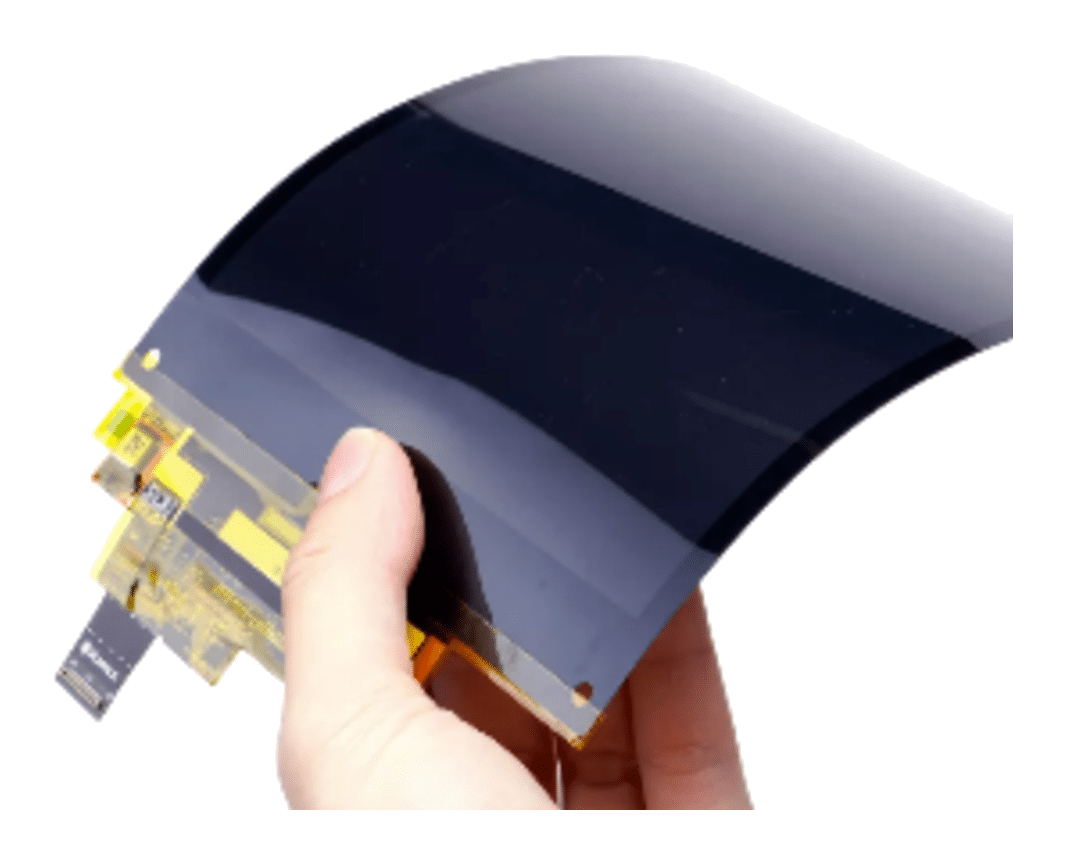

Displays

Inline monitoring, characterization, and qualification of rigid and flexible ITOs, TCOs, TCMs nanowires, meshes, and grids

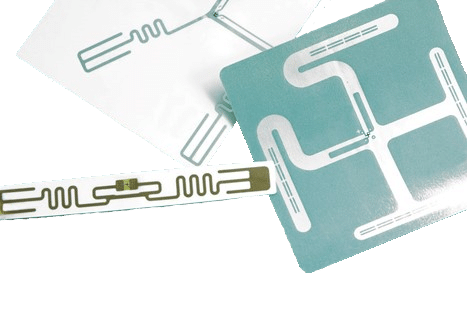

EMI and ESD

Measure sheet resitance of sheidling and disapative coatings, materials, and structures

Flexible Electronics

Measure sheet resistance and thickness. Identify issues such as cracking and bonding failures.

Metalized Films

Inline downsteam and crossweb monitoring in nearly all deposition processes

Thin Film Heaters

Characterize thickness and sheet resistance of rigid and flexible thin film heater elements

Thin Film Solar

CdTe, CIGS, Amorphous silicon, Protocrystalline silicon, Gallium arsenide thin film

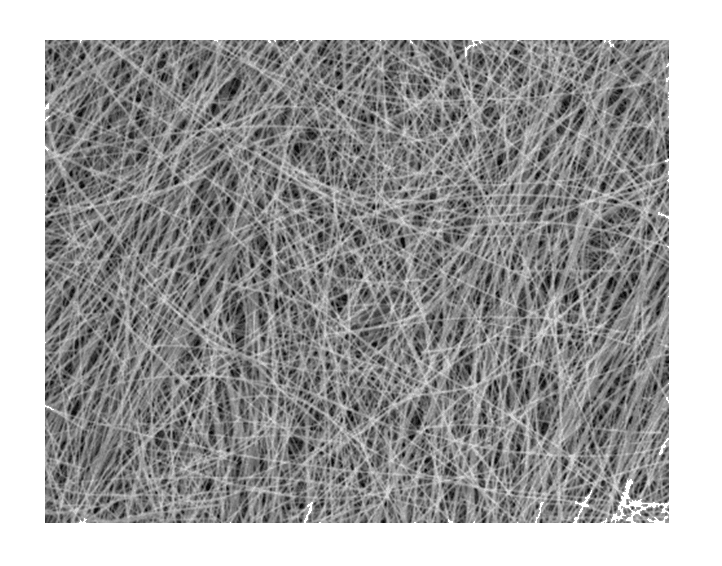

Wires, Meshes, & NanoWires

Characterize sheet resistance of wires, meshes, and nanowires that four point probes cannot measure

Woven Materials

Characterize sheet resistance of woven materials that four point probes cannot measure

Veteran Owned

Veteran Owned Veteran Owned

Veteran Owned